Boiler water sodium ion testing plays a critical role in maintaining the safety, efficiency, and longevity of boiler systems, especially in thermal and nuclear power plants. Even trace amounts of sodium ions can indicate contamination in boiler feedwater and condensate systems, leading to corrosion, scaling, and turbine damage if not addressed in time.

With increasingly strict water quality standards and higher operating pressures, industries now require more accurate and reliable sodium ion testing solutions. This article explains why boiler water sodium ion testing matters, explores common testing methods, and introduces a professional solution designed for laboratory-grade precision.

Sodium ions are not inherently harmful, but in boiler water systems, they act as an early warning indicator of contamination. Sodium typically enters boiler systems through raw water leakage, resin exchanger failure, or seawater intrusion in coastal power plants.

Because sodium ions travel easily with steam, even very low concentrations can signal serious system issues. If left undetected, sodium contamination may accelerate corrosion, reduce heat transfer efficiency, and increase maintenance costs. For this reason, sodium ion concentration is a key monitoring parameter in boiler feedwater and condensate return systems.

Boiler water sodium ion testing is widely used in:

Thermal and nuclear power plants

Chemical and fertilizer production facilities

Metallurgy and heavy industrial steam systems

High-pressure boiler and turbine operations

In power generation, particularly nuclear facilities, sodium ion monitoring is considered a critical quality control measure rather than a routine check.

Early sodium ion meters relied on analog displays, manual knobs, and basic signal processing. While these instruments provided a general reference, they often suffered from poor stability, limited sensitivity, and operator-dependent errors—especially when measuring ultra-low sodium concentrations.

In high-purity boiler water, where sodium levels are often measured in ppb (parts per billion), traditional meters may fail to deliver consistent and reliable results.

Modern boiler water sodium ion testing is based on ion-selective electrode (ISE) technology. Sodium-specific electrodes convert ion activity into electrical signals, enabling precise measurement even at extremely low concentrations.

This method offers higher accuracy, faster response time, and better repeatability, making it the preferred choice for laboratory testing and continuous monitoring in power plants.

Boiler feedwater and condensate systems operate under high temperature and pressure, which means even minimal contamination can cause significant damage. Sodium ions often exist at trace levels, so detection instruments must provide:

High sensitivity at ppb levels

Stable and repeatable measurements

Minimal interference from other ions

Without sufficient precision, sodium ion data becomes unreliable and unsuitable for decision-making.

Laboratories frequently encounter issues such as inconsistent readings, complex calibration procedures, and electrode contamination. Inadequate instrument design can make sodium ion testing time-consuming and prone to human error, especially in static laboratory measurements.

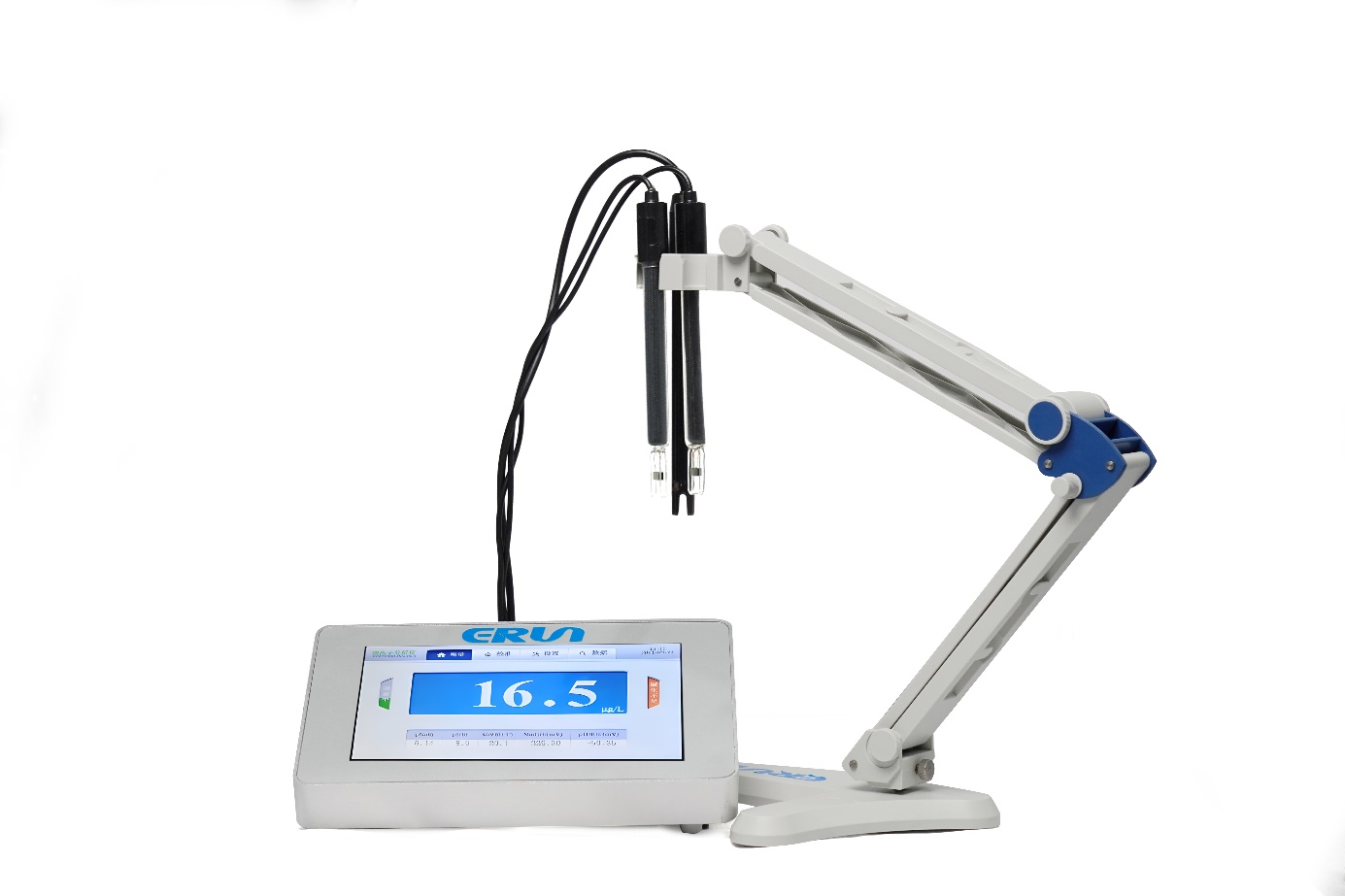

The ERUN-ST3-M6 desktop sodium ion analyzer, developed by Erun Environmental Protection, represents a significant upgrade over older sodium meters. Unlike analog models, it adopts an intelligent digital design with optimized signal processing.

Equipped with specialized sodium ion electrodes, the ERUN-ST3-M6 is capable of ppb-level sodium ion measurement, making it ideal for high-purity boiler water analysis. Its performance in static beaker measurements is significantly improved, offering higher accuracy and improved stability.

Key features include:

High-precision sodium ion detection at trace levels

Stable and repeatable laboratory measurements

Easy electrode cleaning and maintenance

User-friendly operation for laboratory personnel

With proper electrode care, operators can obtain reliable and consistent sodium ion results with minimal effort.

The ERUN-ST3-M6 is well-suited for:

Boiler feedwater sodium ion testing

Condensate return monitoring

Verification of online sodium analyzers

Quality control in power plant laboratories

Its accuracy supports early detection of contamination events, enabling proactive system management.

In addition to boiler water applications, the analyzer is widely used in:

Thermal power generation

Environmental protection laboratories

Pharmaceutical and biochemical research

Food processing and tap water analysis

This versatility makes it a reliable investment for laboratories handling diverse testing requirements.

Contact me for more product details:

WhatsApp: +86 181 8913 5710

Email: stella@xayingrun.com

When selecting an analyzer for boiler water sodium ion testing, consider:

Detection range and ppb-level sensitivity

Measurement stability and repeatability

Ease of calibration and electrode maintenance

A professional desktop analyzer often delivers better performance than basic field meters for critical laboratory testing.

Desktop sodium ion analyzers provide enhanced control, improved signal stability, and higher measurement accuracy. They are commonly used as reference instruments to validate online monitoring systems and support long-term boiler water quality management.

Boiler water sodium ion testing is essential for protecting boilers, turbines, and steam systems from contamination-related damage. Accurate ppb-level sodium detection allows power plants and industrial users to identify problems early and maintain stable operations.

With its advanced electrode technology, intelligent design, and laboratory-grade precision, the ERUN-ST3-M6 desktop sodium ion analyzer offers a reliable solution for modern boiler water sodium ion testing.

To learn more about professional sodium ion analyzers or request technical support, visit erunwas.com.