Total Organic Carbon (TOC) has become one of the most important indicators in modern water treatment. Whether in pharmaceutical manufacturing, power generation, electronics production, or municipal water purification, TOC monitoring helps ensure safety, compliance, and consistent process quality. But what exactly is TOC, and why do industries rely so heavily on it?

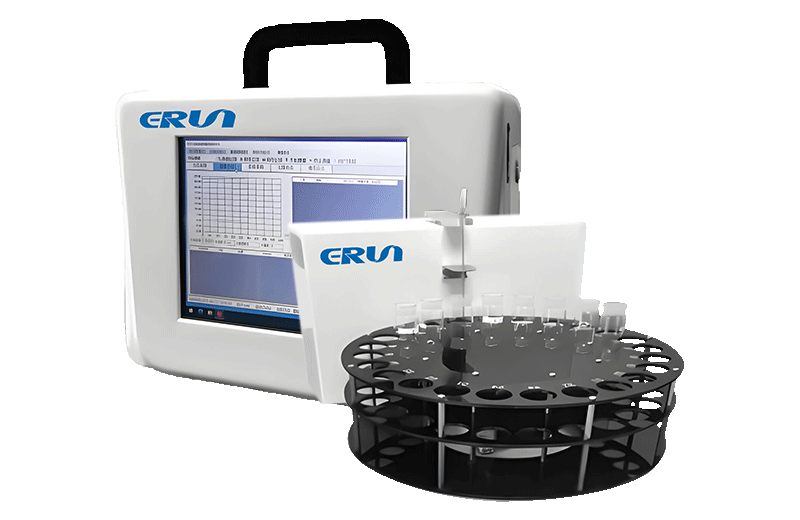

In this article, we break down what TOC is, why it matters, how it is measured, and how advanced TOC analyzers—like the ERUN-SP3-J3 Total Organic Carbon Analyzer—are transforming water quality monitoring with greater accuracy and efficiency.

TOC (Total Organic Carbon) refers to the total amount of carbon contained in organic molecules within water. These organic compounds may come from natural sources—such as plant material or microorganisms—or from industrial sources, including chemical residues, solvents, lubricants, and pharmaceutical components.

In water treatment, TOC is a critical measure because:

Organic contamination can compromise product quality in pharmaceutical and electronics manufacturing.

Excess organic matter can increase the formation of disinfection by-products (DBPs) in drinking water.

High TOC levels may indicate pollution, equipment failure, or microbial growth.

Unlike traditional chemical oxygen demand (COD) or biochemical oxygen demand (BOD) tests, TOC provides a faster and more accurate reflection of organic pollution—making it an essential parameter for real-time monitoring and regulatory compliance.

Regulations such as USP <643> require continuous TOC monitoring for:

Water for Injection (WFI)

Purified Water (PW)

Pharmaceutical-grade process water

Even trace organic contaminants can affect drug safety and stability.

High TOC levels increase the risk of harmful disinfection by-products (DBPs) when water is treated with chlorine.

In power plants, TOC monitoring prevents:

Corrosion

Scaling

Organic fouling in heat exchangers

Semiconductor and microelectronics production requires water with extremely low TOC to avoid defects and conductivity changes.

TOC analyzers typically measure carbon content by breaking down organic molecules and quantifying the carbon dioxide (CO₂) produced. The most common methods include:

Organic compounds are combusted at 680–1,000°C, and the released CO₂ is detected.

Ultraviolet light and persulfate rapidly oxidize organic carbon—ideal for online monitoring.

This involves removing inorganic carbon (IC) by acidification and purging, then measuring the remaining organic carbon.

Modern TOC analyzers integrate multiple methods to improve accuracy across various water quality levels.

To meet the industry’s increasing demand for fast and accurate monitoring, the ERUN-SP3-J3 Total Organic Carbon Analyzer offers advanced features designed for precision and versatility.

Full-range carbon detection: TC, TOC, TIC, NPOC

Compatible with multiple water types:

WFI, purified water, deionized water, power plant water, drinking water, and raw water sources

High accuracy using advanced oxidation technology

Suitable for pharmaceutical, energy, electronics, and water treatment facilities

Reliable performance in ultra-low TOC monitoring scenarios

The ERUN-SP3-J3 helps organizations achieve:

Faster analysis with real-time monitoring

Reduced risk of contamination

Higher process efficiency

Easier compliance with international water quality standards

If your industry depends on high-purity water, an accurate and stable TOC analyzer is essential—and the ERUN-SP3-J3 delivers the precision required for modern water treatment operations.

Total Organic Carbon is far more than a simple water quality metric—it is a direct indicator of contamination, system performance, and regulatory compliance. As industries adopt higher-quality standards, the need for precise TOC measurement continues to grow.

With advanced instruments like the ERUN-SP3-J3 TOC Analyzer, facilities can ensure:

Reliable monitoring

Better control over purification processes

Compliance with strict global regulations

Safer, cleaner, high-purity water

Accurate TOC analysis is no longer optional—it's a critical component of modern water treatment and industrial quality control.