Pharmaceutical water must meet strict international pharmacopoeia standards to ensure drug safety and efficacy, with Total Organic Carbon (TOC) testing playing a critical role in quality control.

Pharmaceutical water is the lifeblood of drug manufacturing, used in everything from drug formulation to equipment cleaning. To ensure safety and efficacy, international pharmacopoeias like the United States Pharmacopeia (USP), European Pharmacopoeia (Ph. Eur.), and World Health Organization (WHO) International Pharmacopoeia set stringent requirements. These standards regulate water purity, particularly through tests like Total Organic Carbon (TOC) analysis, to prevent contamination and ensure compliance. This article dives into these requirements, focusing on long-tail keywords like “pharmaceutical water quality standards” and “TOC testing compliance” to guide professionals in achieving regulatory adherence.

Water used in pharmaceuticals must be free from contaminants that could compromise drug safety. Impurities, including organic compounds, can affect product stability or patient health. TOC testing measures organic carbon levels, serving as a key indicator of water purity. International standards ensure consistency across borders, protecting patients and manufacturers alike.

Several global pharmacopoeias outline requirements for pharmaceutical water and TOC testing. Here’s a breakdown of the major standards:

United States Pharmacopeia (USP): USP <643> specifies TOC testing for Purified Water (PW) and Water for Injection (WFI). It requires TOC levels below 500 ppb for PW and stricter limits for WFI, ensuring minimal organic contamination.

European Pharmacopoeia (Ph. Eur.): Chapter 2.2.44 details TOC testing, aligning closely with USP but emphasizing system suitability and validation for European markets.

WHO International Pharmacopoeia: Focuses on accessible standards for low-resource settings, requiring TOC testing to confirm water purity for pharmaceutical use.

Japanese Pharmacopoeia (JP): Similar to USP, JP emphasizes TOC for water quality, with slight variations in testing protocols.

These standards share a common goal: ensuring water used in drug production meets strict purity requirements to safeguard patient health.

TOC testing measures the amount of organic carbon in water, indicating potential contamination. It’s a critical quality control tool because organic compounds can harbor microbes or react with drug compounds, affecting safety and efficacy. The process involves:

Sample Collection: Water samples are taken from various points in the purification system.

Oxidation: Organic carbon is oxidized to carbon dioxide, measured via conductivity or other methods.

Comparison to Standards: Results are compared against pharmacopoeia limits (e.g., 500 ppb for USP Purified Water).

System Suitability Testing: Ensures the TOC analyzer is functioning correctly, per USP <643> or Ph. Eur. 2.2.44.

TOC testing is non-specific, meaning it detects all organic carbon, not individual compounds, making it a broad but effective purity indicator.

| Pharmacopoeia | Water Type | TOC Limit (ppb) | Testing Standard |

|---|---|---|---|

| USP | Purified Water | ≤ 500 | USP <643> |

| USP | Water for Injection | ≤ 500 | USP <643> |

| Ph. Eur. | Purified Water | ≤ 500 | 2.2.44 |

| WHO | Pharmaceutical Water | ≤ 500 | WHO Guidelines |

| Japanese Pharmacopoeia | Purified Water | ≤ 500 | JP Monograph |

TOC testing and pharmacopoeia compliance aren’t just theoretical—they’re critical in real-world pharmaceutical manufacturing. Here are two examples:

A multinational pharmaceutical company faced challenges maintaining TOC levels in its Purified Water system. After failing an audit due to inconsistent TOC results, they implemented a robust validation protocol per USP <643>. By upgrading their TOC analyzer and training staff on system suitability testing, they reduced TOC levels to below 400 ppb, passing subsequent audits and ensuring product safety.

A small generics manufacturer in a developing country struggled with WHO International Pharmacopoeia compliance due to limited resources. By adopting portable TOC analyzers and following WHO’s simplified testing guidelines, they achieved consistent water purity, enabling export to international markets.

"Implementing TOC testing per USP <643> transformed our quality control process. We now have confidence in our water system, ensuring compliance and patient safety."

— Quality Manager, Leading Biopharma Company

Complying with international standards isn’t always straightforward. Common challenges include:

Equipment Validation: Ensuring TOC analyzers meet system suitability requirements can be complex and costly.

Variability Across Pharmacopoeias: Slight differences in testing protocols (e.g., USP vs. Ph. Eur.) can complicate global compliance.

Resource Constraints: Smaller facilities may lack access to advanced TOC analyzers or trained personnel.

To overcome these, manufacturers should invest in reliable TOC testing equipment, train staff thoroughly, and stay updated on pharmacopoeia revisions.

To meet international pharmacopoeia requirements for pharmaceutical water, consider these best practices:

Regular System Validation: Validate water purification and TOC testing systems annually, per USP <643> and Ph. Eur. 2.2.44.

Staff Training: Ensure personnel understand pharmacopoeia standards and TOC testing protocols.

Real-Time Monitoring: Use online TOC analyzers for continuous monitoring to catch issues early.

Documentation: Maintain detailed records of TOC tests and system suitability to satisfy audits.

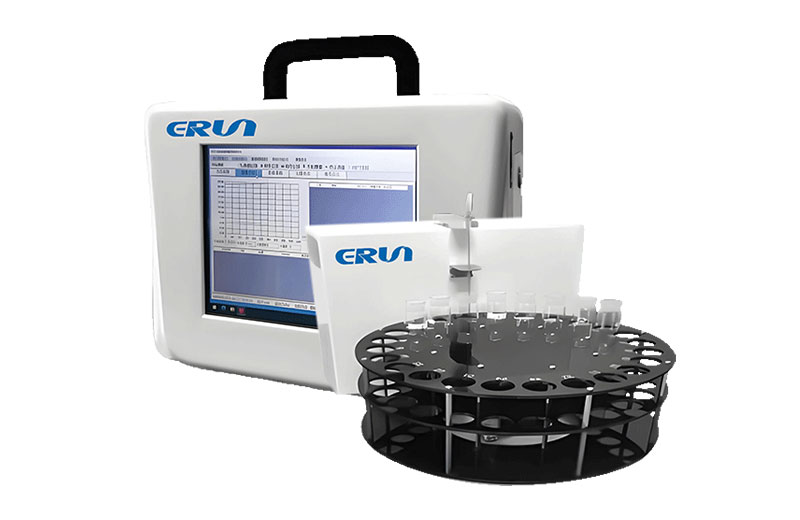

Selecting a TOC analyzer is critical for compliance. Key factors include:

Sensitivity: Must detect low organic carbon levels (e.g., <500 ppb).

Compliance: Ensure compatibility with USP <643>, Ph. Eur. 2.2.44, or other relevant standards.

Ease of Use: Look for user-friendly interfaces to minimize errors.

Maintenance: Choose systems with low maintenance needs for consistent performance.

Popular brands like Sievers and Shimadzu offer analyzers tailored for pharmaceutical applications, meeting global standards.

As global regulations evolve, pharmacopoeias are likely to tighten TOC limits and emphasize real-time monitoring. Emerging technologies, such as advanced oxidation methods and automated TOC analyzers, are making compliance easier and more efficient. Staying ahead of these trends ensures manufacturers remain competitive and compliant.

Meeting international pharmacopoeia requirements for pharmaceutical water and TOC testing is essential for drug safety and regulatory compliance. By understanding standards like USP <643>, Ph. Eur. 2.2.44, and WHO guidelines, manufacturers can ensure water purity, avoid costly audit failures, and protect patients. Implementing best practices, investing in reliable TOC analyzers, and learning from real-world case studies can drive compliance and operational success.

For more insights on pharmaceutical water quality standards or TOC testing compliance, consult your pharmacopoeia of contact a trusted equipment provider today like me.