Water quality testing for TDS, EC, pH, and temperature ensures safe, clean water by measuring dissolved solids, conductivity, acidity, and thermal conditions. Here’s a deep dive into these critical parameters, their importance, and how to test them effectively to optimize water quality for homes, industries, and agriculture.

Water quality testing involves key metrics to assess safety and usability:

TDS (Total Dissolved Solids): Measures dissolved substances (minerals, salts, metals) in water, reported in ppm (parts per million, mg/L).

EC (Electrical Conductivity): Indicates water’s ability to conduct electricity, reflecting ion content, measured in µS/cm (microsiemens per centimeter).

pH: Gauges water’s acidity or alkalinity on a scale of 0-14 (7 is neutral).

Temperature: Affects chemical reactions and sensor accuracy, typically measured in °C.

These parameters, outlined in standards like ISO 7888 (conductivity) and EPA Method 150.1 (pH), are vital for assessing water suitability for drinking, irrigation, or industrial use.

Testing TDS, EC, pH, and temperature ensures water meets safety and performance needs:

TDS: High TDS (>500 ppm for drinking water, per WHO guidelines) may indicate contamination or affect taste. Low TDS can be too pure, lacking essential minerals.

EC: Correlates with TDS; high EC suggests salinity, impacting crops or equipment.

pH: Affects water safety (ideal drinking water pH: 6.5-8.5, per EPA standards) and chemical stability in industrial processes.

Temperature: Influences pH and EC readings and microbial growth rates.

Neglecting these can lead to health risks, equipment damage, or crop failure. Regular testing ensures compliance with international standards like ISO 5667 (water sampling).

Method: Use a handheld TDS meter or gravimetric analysis (evaporating water to measure residue).

Process: Calibrate the meter, dip it in a water sample, and read the ppm value.

Standards: WHO recommends TDS below 500 ppm for drinking; industrial limits vary (e.g., <50 ppm for boilers, per ASME guidelines).

Method: Employ an EC meter, which measures current flow through water.

Process: Insert the probe into the sample, ensuring temperature compensation for accuracy.

Standards: ISO 7888 suggests EC below 1000 µS/cm for drinking water.

Method: Use a pH meter or test strips for quick checks.

Process: Calibrate with buffer solutions (pH 4, 7, 10), then measure the sample.

Standards: EPA Method 150.1 specifies pH 6.5-8.5 for potable water.

Method: Use a digital thermometer or integrated sensors in TDS/pH meters.

Process: Record temperature before other tests, as it affects readings.

Standards: ISO 10523 notes temperature’s role in pH accuracy.

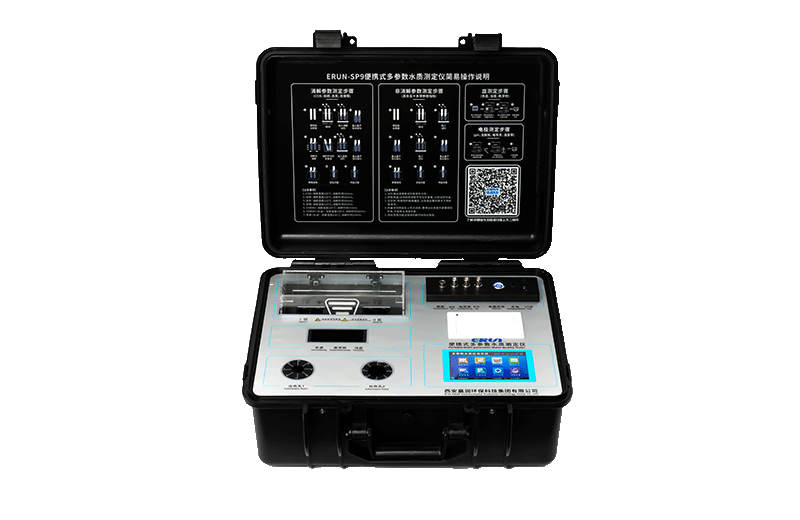

Laboratory Equipment: Spectrophotometers or benchtop meters for precise analysis.

Calibration Kits: Essential for maintaining accuracy, per ISO 17025 standards.

A vineyard in Napa Valley faced crop stress due to high salinity. Testing revealed:

TDS: 1200 ppm (above the 500-1000 ppm ideal for irrigation, per FAO guidelines).

EC: 1800 µS/cm, indicating saline water.

Solution: Installed a reverse osmosis system, reducing TDS to 400 ppm. Yield improved by 15% within a season.

Endorsement: The California Department of Water Resources praised the vineyard’s water management, aligning with ISO 14046 (water footprint standards).

A manufacturing plant reported boiler scaling. Testing showed:

pH: 9.5 (too alkaline, risking corrosion).

TDS: 200 ppm (within ASME boiler limits).

Solution: Adjusted pH to 8.0 using acid dosing and monitored temperature to optimize chemical dosing. Maintenance costs dropped by 20%.

Calibrate Regularly: Ensure meters are calibrated per manufacturer guidelines.

Test at Consistent Times: Temperature fluctuations affect readings.

Use Clean Containers: Avoid contamination during sampling.

Log Data: Track trends to identify issues early, per ISO 5667 protocols.

Consult Standards: Reference WHO, EPA, or ISO guidelines for compliance.

Per WHO, 50-500 ppm is ideal. Higher levels may affect taste; lower levels may lack minerals.

Temperature impacts pH and EC readings. Most meters auto-compensate, but manual checks should note temperature, per ISO 10523.

Yes, multi-parameter meters (e.g., Oakton PC2700) measure TDS, EC, pH, and temperature, ensuring efficiency.

Testing water for TDS, EC, pH, and temperature is crucial for safety, efficiency, and compliance with standards like ISO 7888 and EPA Method 150.1. Whether for drinking, agriculture, or industry, accurate testing prevents health risks and equipment issues. Ready to optimize your water quality? Explore our range of testing tools and professional services at our website for tailored solutions!