Hot water boiler water quality testing indicators include turbidity, hardness, pH, conductivity, and dissolved oxygen. Multi-parameter instruments like the ERUN-SP9-11 ensure accurate, efficient monitoring. Let’s explore the details!

Water quality is vital for the safe and efficient operation of hot water boilers. Poor quality can lead to scaling, corrosion, or even accidents. According to the Boiler Green and Low-Carbon Development Action Plan (2023) by China’s National Energy Administration, enhanced water quality monitoring is key to improving boiler efficiency and safety. The plan aims for a 2% increase in average boiler thermal efficiency by 2025 compared to 2020, highlighting significant energy-saving potential. Research shows that 1mm of scale buildup can reduce thermal efficiency by 2-5% (Source: Industrial Boiler Energy-Saving Technology Study, China Energy Research Society, 2022).

Regular testing prevents downtime and losses by identifying issues early. The GB/T 1576-2018 standard, applicable to boilers with steam pressure below 3.8MPa, outlines feedwater and boiler water requirements. For instance, feedwater turbidity should be ≤5 NTU and hardness ≤0.6 mmol/L for boilers ≥4.2MW.

Feedwater quality sets the foundation for boiler performance. GB/T 1576-2018 specifies key indicators:

Turbidity: ≤5 NTU to prevent sediment buildup and ensure heat transfer.

Hardness: ≤450 mg/L (as CaCO₃) or ≤0.6 mmol/L for high-capacity boilers to avoid scaling.

pH: 7.0-9.0 to maintain neutrality and prevent corrosion.

Iron Content: ≤0.3 mg/L to minimize rusting.

Dissolved Oxygen: ≤0.1 mg/L to reduce metal oxidation.

Multi-parameter instruments streamline testing, saving time. The National Development and Reform Commission notes that optimized feedwater can cut boiler energy use by over 10% (Source: Boiler Green Development Plan, 2023). Neglecting dissolved oxygen testing in small boilers can shorten lifespan by 20%.

Boiler water (furnace water) indicators focus on operational conditions. Key GB/T 1576-2018 requirements include:

pH: 10.0-12.0 for an alkaline environment to prevent corrosion.

Phosphate: 5-20 mg/L for water softening.

Conductivity: ≤80 μS/cm to control salt buildup.

Total Alkalinity: Adjusted based on pressure to avoid acidic corrosion.

Chloride: ≤300 mg/L to prevent stress corrosion.

Weekly testing is recommended. High conductivity increases blowdown frequency, wasting energy. The 2023 plan highlights that retrofitting existing boilers can boost efficiency by 5%, with water quality as a foundation (Source: National Energy Administration, 2023). Electrode-based instruments ensure real-time, accurate monitoring.

Multi-parameter analyzers are ideal for hot water boilers, testing multiple indicators simultaneously. Key features include:

Portable Design: Battery-powered for on-site use.

High-Precision Sensors: ±1-5% error for pH, conductivity, etc.

Data Storage: Enables export for compliance and analysis.

User-Friendly Interface: No need for advanced chemical expertise.

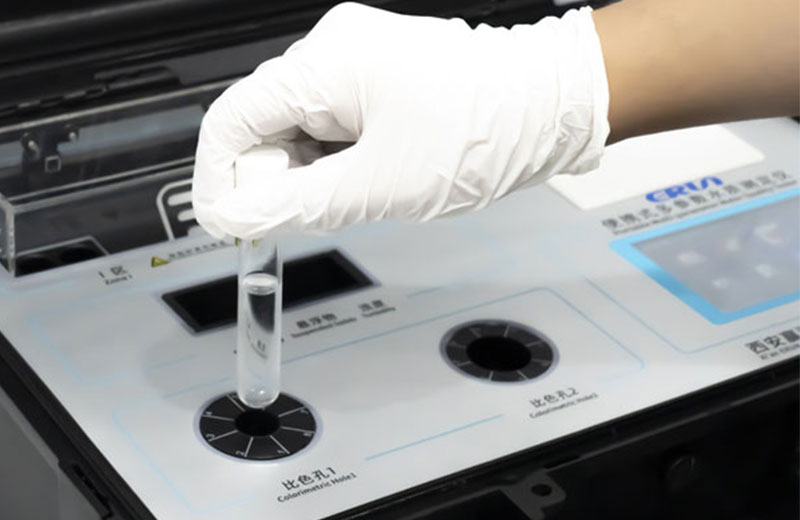

The ERUN-SP9-11, with a 16-channel optical system, measures over 60 parameters, perfectly suiting hot water boilers. It’s 30% more efficient than single-parameter devices, reducing costs (Source: ERUN Environmental Report, 2025).

A Xi’an heating company faced efficiency issues with a boiler operating at 85% due to scaling. After adopting the ERUN-SP9-11, daily hardness and pH monitoring allowed timely softener adjustments. Scaling dropped 30%, saving $21,000 annually in fuel costs. The setup met GB/T 1576-2018 standards, aligning with the action plan’s focus on operational excellence (Source: Company Report, 2024).

| Indicator | Range | Accuracy | Instrument Example |

|---|---|---|---|

| Turbidity | 0-400 NTU | ±2% | Multi-Parameter Optical |

| Hardness | 0.1-500 mg/L | ±5% | Electrode/Colorimetric |

| pH | 0-14 | ±0.01 | Glass Electrode |

| Dissolved Oxygen | 0-20 mg/L | ±0.2 mg/L | Fluorescence Sensor |

| Conductivity | 0-200 mS/cm | ±1% | Conductivity Meter |

(Source: GB/T 1576-2018 and Instrument Manuals). Prioritize standard-compliant, durable instruments.

A boiler technician shared, “Switching to a multi-parameter analyzer cut testing time from half a day to 30 minutes. The data’s spot-on, preventing several potential issues.” ERUN’s CE-certified products, trusted in the power sector, offer proven reliability. Per the action plan, such investments yield high returns, often recovering costs within two years.

Start with your needs: portable devices for small boilers, online systems for large setups. Consult manufacturers for tailored solutions, ensuring GB/T 1576-2018 compliance. ERUN Environmental offers free demos—check out the ERUN-SP9-11 at https://www.erunwqs.com/products-detail/id-463.html.

Hot water boiler water quality testing indicators and instruments are vital for safety and efficiency. Following GB/T 1576-2018 and the action plan, tools like the ERUN-SP9-11 ensure reliability. Act now to optimize your boiler system!